Aluminium extrusion inyanzvi yekugadzira uye inoshanda zvakasiyana-siyana inoshandiswa kugadzira zvikamu zvine chaiwo muchinjika-chikamu profiles. Pamwoyo weichi chiitiko pane chimwe chezvinhu zvinonyanya kukosha:iyo extrusion inofa. Ichi chakanyatso-engineered turusi inoumba aluminium pasi pekumanikidzwa kukuru uye inoita basa rakakosha mukuona mhando yechigadzirwa, kupera kwepasi, uye kurongeka kwedimensional.

Chii chinonzi Aluminium Extrusion Die?

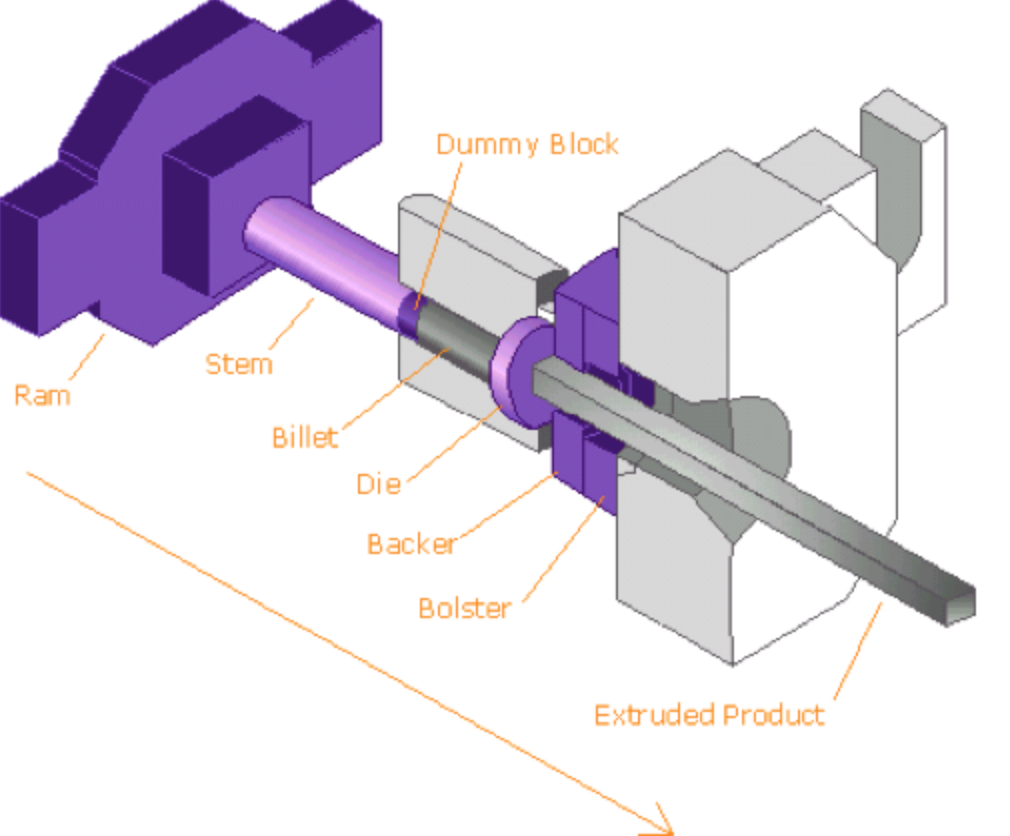

An extrusion die isimbi yakagadzirwa yakanyatsogadzirwa ine chaiyokufa kuvhuraiyo inoumba iyo aluminium sezvainomanikidzwa kuburikidza nekumanikidzwa kwakanyanya. Pamwe chete nematurusi ekutsigira akadai sevanodzosera, bolsters, uye sub-bolsters, iyo inofa inovimbisa kurongeka kwakaringana uye kurongeka kwechimiro panguva yekuwedzeredza.

Mhando dzeExtrusion Inofa

Extrusion anofa akaiswa mumhando nhatu huru zvichienderana neinodiwa mbiri geometry:

1. Solid Dies

Inoshandiswa kugadzira maprofile pasina chero cavities - senge mabara, makona, kana chiteshi.

● Zvikamu:

○ Die Plate: Iine yakaumbwa orifice yeiyo yekupedzisira mbiri.

○Backer Plate: Inopa rubatsiro kuseri kwekufa.

○Chekudya chekudya (chisarudzo): Inobatsira mukutungamira kuyerera kwezvinhu.

2. Hollow Inofa

Yakagadzirirwa maprofiles ane ma voids emukati senge machubhu kana mafaremu emahwindo.

●Zvikamu:

○Mandrel (kana musimboti): Inoumba mhango yemukati.

○Die Cap: Inoumba chimiro chekunze uye inobata mandrel panzvimbo.

○Backer: Inopa tsigiro yezvimiro uye kutonga kwekupisa.

3. Semi-Hollow Inofa

Inoshandiswa kumaprofile ane akavharirwa zvishoma - kusanganisa maficha ezvikamu zvakasimba uye zvisina mhango. Aya akanakira ma geometries akaoma uye akasiyana madziro makubvu.

Iyo Extrusion process uye iyo Die's Basa

Matanho akakosha eextrusion anosanganisira:

1.Billet Preheating:

Aluminium billets anopisa kusvika 370-500 ° C (700-930 ° F) kuvandudza plastiki.

2.Loading & Extrusion:

Billet inotakurwa mumudziyo, uye gondohwe re hydraulic (nekumanikidza kubva ku1,000 kusvika ku15,000 matani) inoisundira kuburikidza nekufa.

3.Profile Formation:

Iyo aluminium inotora chimiro chekuvhura kwefa painobuda, ichigadzira iyo inodiwa chimiro.

4.Kutonhodza, Kucheka & Kupedza:

Maprofayiri akatonhodzwa, akatambanudzwa, akachekwa kureba, uye anogona kupedzwa pamusoro senge anodizing kana poda coating.

Panguva yese iyi,iyo inofa inovimbisa kurongeka kwechimiro, kunaka kwepamusoro, uye kuenderana.

Kufa-Kunoenderana Kushivirira uye Wall Thickness Control

Precision yakakosha. Aluminium extrusion kushivirira kunoenderana ne:

●Profile saizi & kuoma

●Kukora kwemadziro(madziro akaonda kwazvo anowedzera kuoma)

●Kufa kupfeka nekufamba kwenguva

●Kukora kwemadziroinogona kusiyanisa zvishoma, kunyanya pakufa kutsva - ekutanga extrusions inogona kutetepa zvishoma, asi nekushandisa, inofa yakagadzikana uye zvirinani inoenderana nemadhizaini ezita. Ichi ndicho chikonzeromabhechi anoteverakazhinji kuratidza kukora zvishoma uye kuenderana mhedzisiro.

Kushivirira kwakajairwa kunodzorwa nemaitiro epasi rose akadaiEN 755-9kanaAA (Aluminium Association)specifications.

Die Surface Treatments uye Maintenance

Kuti uvandudze mashandiro uye hupenyu hwehupenyu, extrusion inofa inowanzoitwa:

Nitriding

Maitiro ekuomesa epamusoro anoparadzira nitrogen munzvimbo inofa, ichiwedzera kuomarara uye kupfeka kuramba - kwakakosha pakubata yakanyanya kudzvanywa uye tembiricha.

Die Preheating (Die Cooking)

Uyewo anozivikanwa se“煲模(bao mo)” muchiChinese, tsika iyi inopisa zvishoma nezvishoma mufi isati yawedzera kuderedza kupisa uye kunatsiridza kuyerera kwesimbi.

Zvakajairwa Kufa Zvinetso uye Dziviriro Maitiro

✅ Kupfeka uye Kubvarura

High pressure uye tembiricha zvinokonzera kupera zvishoma nezvishoma.Kugara uchiongorora, kukwenenzverazve, uye re-nitridingwedzera hupenyu hwekufa.

✅ Kukanganisa Kwepamusoro

Kukwenya, mitsetse yekufa, kana kuvaka kunogona kukanganisa kunaka kwepamusoro. Routinekufa kuchenesauyepamusoro mishongakubatsira kuderedza kuremara.

✅ Thermal Management

Kupisa kusina kuenzana kana kutonhora kunotungamirira kukuremara kana kufa kuparara. Insulation yakakodzera uye inodzorwa preheating yakakosha.

✅ Kuenderana uye Tsigiro

Kurongeka kwakashata kunokonzeresa kukanganisa kwedimensional uye kutadza kufa nekukurumidza. Periodicre-calibrationuyekuchengetedzazvakakosha pakurongeka.

Sei Kufa Kunokosha muAluminium Extrusion

Iyo yakanyatsogadzirwa, inochengetedzwa zvakanaka extrusion inofa inokanganisa zvakananga:

●Dimensional kururama

●Profile kuoma

●Extrusion speed

●Surface finish

●Yese mutengo wechigadzirwa uye kuenderana

Kusarudza iyo chaiyo yekufa mhando, kunzwisisa madziro ukobvu manejimendi, uye kuita yakasimba yekudzivirira kuchengetedza maitiro kwakakosha kuti uwane inowirirana, yemhando yepamusoro mhedzisiro.

Kutsvaga Yakavimbika Custom Die & Extrusion Partner?

Pa[Zita reKambani Yako], isu tinoshanda mukunyatso aluminium extrusion uye tinopa rutsigiro rwakazara rwecustom die development, profile optimization,uyekufa kwehupenyu-kutenderera manejimendi. Kunyangwe iwe uri kugadzira akasimba, maburi, kana akaomarara mahybrid profiles, timu yedu yeinjiniya yakagadzirira kubatsira nehunyanzvi hwekuona uye kugadzira kwakavimbika.

Bata nesu nhasikuti udzidze zvakawanda nezve maitiro atingaite kuti magadzirirwo ako ave nehupenyu neakakodzera extrusion mhinduro.

Email: will.liu@aluminium-artist.com

Webhusaiti: www.aluminium-artist.com

Kero:Pingguo Industrial Zone, Baise Guta, Guangxi, China

Nguva yekutumira: Jun-17-2025