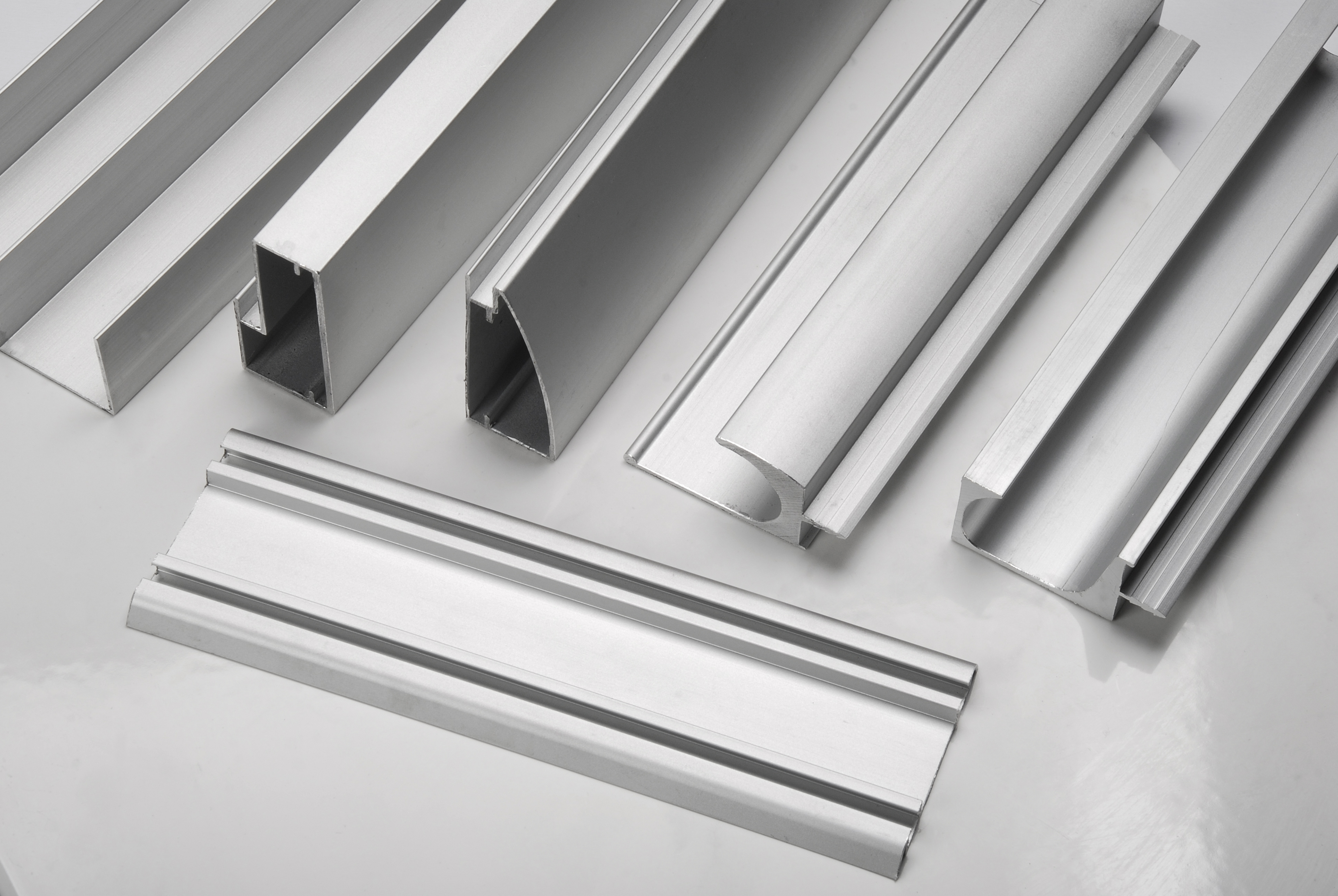

Aluminium chinhu chakakosha chakakosha zvinhu. Muhupenyu hwezuva nezuva, isu tinogona kazhinji kuona kushandiswa kwealuminium profiles mukuvaka magonhi,mahwindo, madziro emaketeni, kushongedza kwemukati nekunze uye zvivakwa zvekuvaka.

Architectural aluminiyamu profiles ane chaiwo zvinodiwa pakumisikidzwa uye kugadzirwa kwakawanda, uye iyo aluminium tsvimbo extrusion process inowanzo shandiswa kuwana mhinduro yakagadziridzwa yekugadzira nekugadzira. Pfungwa huru yealuminium profil extrusion ndeyekuisa imwe kudzvanywa pane aruminiyamu tsvimbo muextrusion barrel kuita kuti aruminiyamu alloy ibude kubva mugomba rekufa, nekudaro uchiwana maaluminium profiles emhando chaiyo uye saizi. Iyi extrusion yekugadzirisa nzira ine mutengo wakaderera, kushanda kwakanyanya uye nyore kushanda, uye inotora chikamu chakati wandei muhurongwa hwemazuva ano hwekugadzira maindasitiri. Ichi chinyorwa chichatarisa pane extrusion yekugadzira maitiro ealuminium profiles, ichitibvumira kuti tive nekunzwisisa kwakadzama kwealuminium profiles zvigadzirwa:

1. Kugadzirwa kwezvinhu zvakasvibiswa

Zvinoenderana neyakaverengerwa kuumbwa kweyero yearuminiyamu profiles inodiwa, zvakasiyana-siyana mbishi zvinhu zvine musoro.Iyo aruminiyamu ingot inopisa kune imwe tembiricha yekunyunguduka, uye imwe chiyero chealloying element inowedzerwa kune yakanyungudutswa aruminiyamu fluid (magnesium nesilicon zvinowanzowedzerwa kune system system uye hwindo chigadzirwa mitsetse). Iyo slag uye gasi remarara mukunyunguduka kunobviswa nenzira dzinoenderana dzekunatsa.Pasi pemamiriro ekukanda akakodzera, iyo yakanyungudutswa yealuminium liquid inodururwa mumushini wekukanda, yakanyoroveswa uye inokandwa mumativi akakanda matanda ane madhayamita uye zvirevo zvinosangana nezvinotarisirwa.

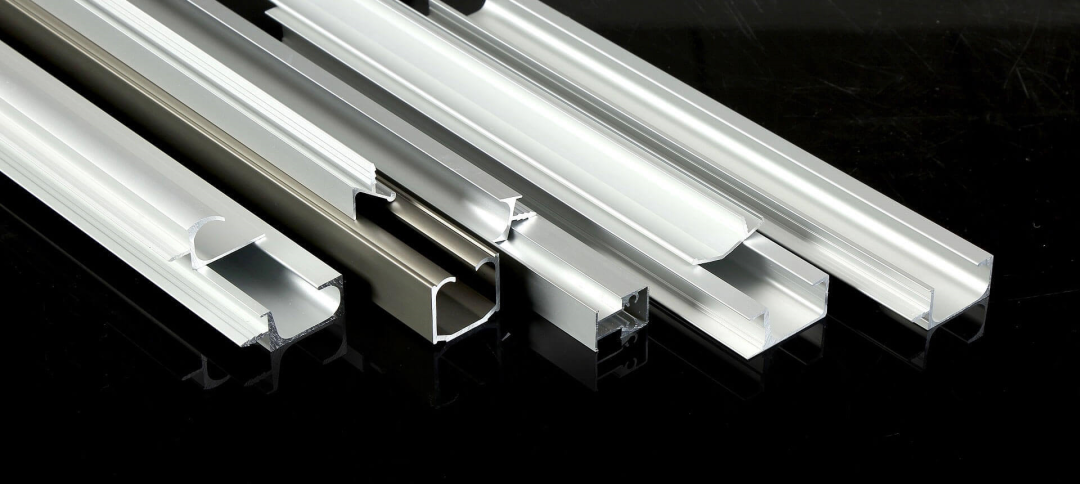

2. Aluminium tsvimbo extrusion

① Isa simbi dzealuminium dzakafuratira pane rack yemidziyo, dzivirira kuva padhuze nepadhuze kana kuarongedza, uye chengetedza nzvimbo yakachengeteka yekuvhiya kudzivirira matanda ealuminium kuti asakunguruke kana kudonha.

②Kupisa simbi yealuminium uye mold muchoto kuti ukwidze tembiricha kusvika 480°C, uye uchengete ichidziya kweawa imwe isati yagadziriswa;

③Isa mold mufa base ye extruder, isa aluminium tsvimbo muchiteshi chekudya che extruder uye gadzirira extrusion;

④ Iyo yakawedzera mbiri inobuda mugomba rekuburitsa, uye musoro wezvinhu unodhonzwa netirakita, uye kucheka kwekutanga kunoitwa zvichienderana nehurefu hwakatarwa uye saizi.

3. Kururamisa

Aluminium profiles inokweverwa neextrusion kazhinji haigone kutwasanuka, iyo inokanganisa kushandiswa kunotevera kana kushanda pamichina yemagetsi.Iyo yakawedzera aluminium profiles inotumirwa kutafura yekururamisa kururamisa, uye yozotakurwa kune yakapedzwa chigadzirwa nzvimbo yekucheka kusvika kureba.

4. Kurapa kwenguva

Kuisa aluminium alloy profile material muchoto chekuchembera kuti upise kune imwe tembiricha uye kuichengeta ichidziya kwemaawa 2-3 inogona kuvandudza zvakanyanya ma mechanical ealuminium alloy profile, kunyanya kuoma kwezvinhu.Isa ma profiles akachekwa aruminiyamu mufuremu yezvinhu, uende nawo kunzvimbo yekuchembera, uye pinda muchoto chekuchembera kuitira kurapwa kuchembera. Kana tembiricha yekuchembera yasvika 200 ℃, chengeta ichidziya kwemaawa maviri, wozomirira kuti iburitswe;Kana kuchembera kwapera, inogona kuburitswa muchoto yopinda munhanho yekutonhodza. Inogona kutonhodzwa zvakasununguka kana kuti yakagadzirwa nemhepo inotonhorera.Panguva iyi, basa re extrusion rinopera, uye extrusion yealuminium profiles ine maitiro akakodzera ekuonekwa uye chimiro uye saizi inopedzwa.

5. Kurapa kwepamusoro

Isa mushonga wepamusoro wakakodzera sezvinodiwa. Parizvino, kune akati wandei anozivikanwa epamusoro ekurapa maitiro mumusuwo wesystem uye indasitiri yehwindo: anodizing, electrophoresis, porcelain coating, fluorocarbon spraying, nezvimwe.

Bata ne us kuti uwedzere kubvunza.

Tel/WhatsApp: +86 17688923299

E-mail: aisling.huang@aluminum-artist.com

Nguva yekutumira: Aug-31-2023