Chikamu 2. Tekinoroji: aluminium extrusion + friction inosimudzira welding seyakanyanya, laser welding uye FDS kana kuve iyo ramangwana kutungamira.

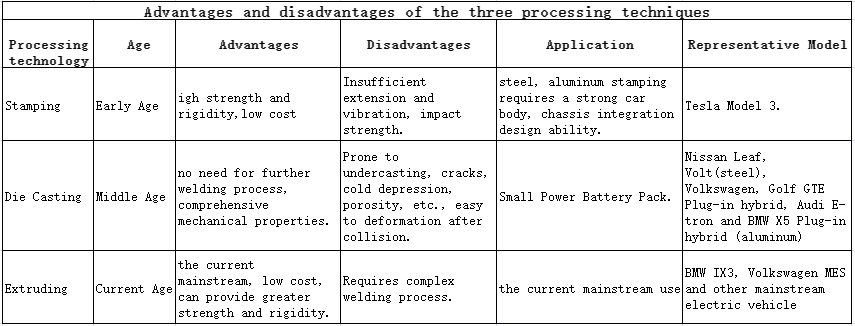

1. Kuenzaniswa nekufa kukandira uye kutsika, aruminiyamu extrusion inogadzira profiles uye ipapo welding ndiyo huru tekinoroji yemabhokisi ebhatiri parizvino.

1) Kudzika kwakadzika kwegoko pasi pebhatiri paki yakashongedzerwa neinotsikisa aluminium ndiro, iyo isina kukwana vibration uye simba rekuita rebhatiri pack, uye mamwe matambudziko anoda kuti mabhizinesi emotokari ave nesimba rakabatana dhizaini kugona kwemuviri uye chassis;

2) Iyo yekukanda aluminium bhatiri tireyi mu die casting mode inotora iyo yese-imwe-nguva kuumba. Izvo zvisingabatsiri ndezvokuti iyo aluminium alloy inowanzoita undercasting, kuputika, kutonhora kwega, kuora mwoyo, porosity uye kumwe kukanganisa mukukanda. Iyo yekuisa chisimbiso pfuma yechigadzirwa mushure mekukanda yakashata, uye kurebesa kweakakandirwa aluminium alloy yakaderera, iyo inokonzeresa deformation mushure mekudhumhana;

3) Yakawedzera aluminium alloy bhatiri tireyi ndiyo yazvino bhatiri dhizaini dhizaini dhizaini, kuburikidza nekubatanidza uye kugadzirisa maprofile kuti asangane nezvinodiwa zvakasiyana, ine zvakanakira dhizaini inoshanduka, kugadzirisa zviri nyore, nyore kugadzirisa uye zvichingodaro; Performance Extruded aluminium alloy bhatiri tireyi ine yakanyanya kuoma, vibration kuramba, extrusion uye kukanganisa kuita.

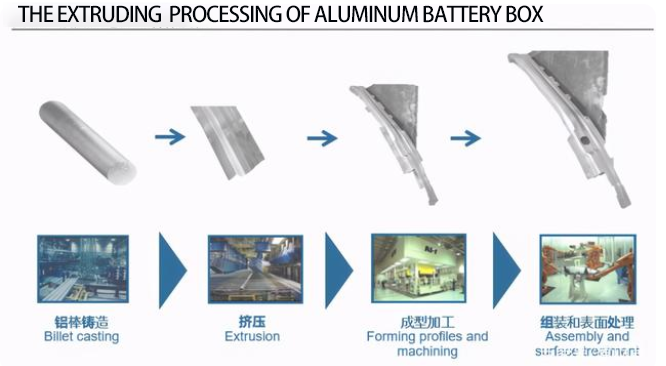

2. Kunyanya, maitiro ealuminium extrusion kuumba bhatiri bhokisi ndeaya anotevera:

Iyo yepasi ndiro yebhokisi body inoumbwa ne friction stir welding mushure mekunge aruminiyamu bar yabviswa, uye bhokisi rezasi rinoumbwa nekukandwa nemahwendefa mana eparutivi. Parizvino, iyo yakajairika aluminium mbiri inoshandisa yakajairwa 6063 kana 6016, iyo tensile simba iri pakati pe220 ~ 240MPa, kana kushandiswa kwesimba repamusoro rakaburitswa aruminiyamu, simba rekusimba rinogona kusvika kupfuura 400MPa, zvichienzaniswa neyakajairwa aluminium profil box inogona kuderedza huremu ne20% ~30%.

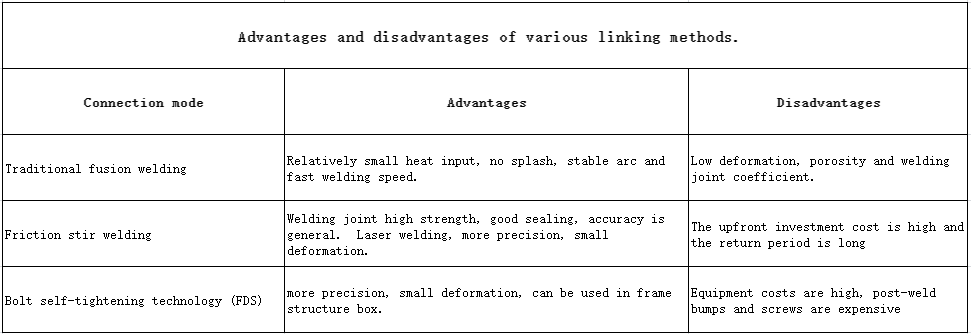

Nekuda kwekuda kwekubatanidza iyo mbiri, welding tekinoroji ine simba guru pakudzikama uye kurongeka kwebhokisi rebhatiri. Battery box welding tekinoroji yakakamurwa kuita yechinyakare welding (TIG welding, CMT), uye ikozvino mainstream friction welding (FSW), yakawedzera advanced laser welding, bolt self-tightening tekinoroji (FDS) uye bonding tekinoroji.

TIG welding iri pasi pekuchengetedzwa kwegasi inert, uchishandisa arc inogadzirwa pakati petungsten electrode uye weldment kupisa base melt base simbi uye kuzadza waya, kuitira kuti igadzire emhando yepamusoro welds. Nekudaro, nekushanduka kwechimiro chebhokisi, saizi yebhokisi inova yakakura, chimiro cheprofile chinova chitete, uye kurongeka kwedimensional mushure mekushongedza kunovandudzwa, TIG welding iri panjodzi.

CMT iyi itsva MIG/MAG welding process, uchishandisa yakakura pulse ikozvino kuita welding wire arc mushe, kuburikidza neiyo material surface tension, giravhiti uye mechanical kupomba, kugadzira inoenderera weld, ine diki yekupisa inopinza, pasina splash, arc kugadzikana uye kukurumidza welding kumhanya uye zvimwe zvakanakira, zvinogona kushandiswa kune zvakasiyana-siyana zvekushandisa welding. Semuenzaniso, chimiro chebhokisi pasi pebhatiri pasuru inoshandiswa neBYD neBAIC modhi inowanzotora CMT welding tekinoroji.

4. Traditional fusion welding ine matambudziko akadai sedeformation, porosity uye yakaderera welding joint coefficient inokonzerwa nekupinza kukuru kwekupisa. Naizvozvo, inoshanda zvakanyanya uye yakasvibira friction inosimudzira welding tekinoroji ine yepamusoro welding mhando yakashandiswa zvakanyanya.

FSW yakavakirwa pakupisa kunogadzirwa nekukweshana pakati peinotenderera inosanganisa tsono uye shaft fudzi nesimbi yepasi senzvimbo yekupisa, kuburikidza nekutenderera kwetsono yekusanganisa uye axial simba reshaft pfudzi kuti iwane kuyerera kwepurasitiki yesimbi yepasi kuti uwane iyo welding yekubatanidza. FSW welding joint ine simba rakawanda uye kuita kwakanaka kwekuisa chisimbiso kunoshandiswa zvakanyanya mumunda webhatiri bhokisi welding. Semuenzaniso, bhokisi rebhatiri remhando dzakawanda dzeGeely neXiaopeng rinotora kaviri-mativi friction inosimudzira welding chimiro.

Laser welding inoshandisa Laser danda ine high simba density kuti irradiate pamusoro pezvinhu kuti zvive welded kunyungudutsa zvinhu uye kuumba mubatanidzwa wakavimbika. Laser welding michina haisati yashandiswa zvakanyanya nekuda kwemutengo wakakura wekudyara kwekutanga, nguva refu yekudzoka, uye kuoma kwealuminium alloy laser welding.

5. Kuti uderedze kukanganiswa kwekugadzirisa kusvibiswa kwebhokisi kururamisa kwehukuru hwebhokisi, bhoti yekuzvisimbisa tekinoroji (FDS) uye tekinoroji yekubatanidza inounzwa, pakati peiyo makambani anozivikanwa ari WEBER muGermany uye 3M muUnited States.

FDS yekubatanidza tekinoroji imhando yekutonhora yekugadzira maitiro ekuzvirova-tapa screw uye bhaudhi yekubatanidza kuburikidza nekusimbisa shaft yenzvimbo yemidziyo kuti iite kutenderera kwekumhanya kwemota kuti ibatanidzwe kune kupisa kweplate friction uye deformation yepurasitiki. Inowanzo shandiswa nemarobhoti uye ine yakakwirira dhigirii ye automation.

Mumunda wesimba idzva rekugadzira bhatiri paki, maitiro acho anonyanya kushandiswa kune furemu chimiro bhokisi, ine bonding process, kuitira kuti ive nechokwadi chakakwana chekubatanidza simba uchiona kuvharwa kwebhokisi. Semuenzaniso, iyo bhatiri kesi yeMotokari modhi yeNIO inoshandisa tekinoroji yeFDS uye yakagadzirwa zvakanyanya. Kunyangwe tekinoroji yeFDS ine mabhenefiti ari pachena, zvakare ine zvayakaipira: mutengo wemidziyo wakakwira, mutengo wakakwira wemashure-weld protrusions uye screws, nezvimwewo, uye mamiriro ekushanda anoderedzawo kushandiswa kwayo.

Chikamu 3. Mugove Wemusika: bhatiri bhokisi musika nzvimbo yakakura, nekukurumidza komputa kukura

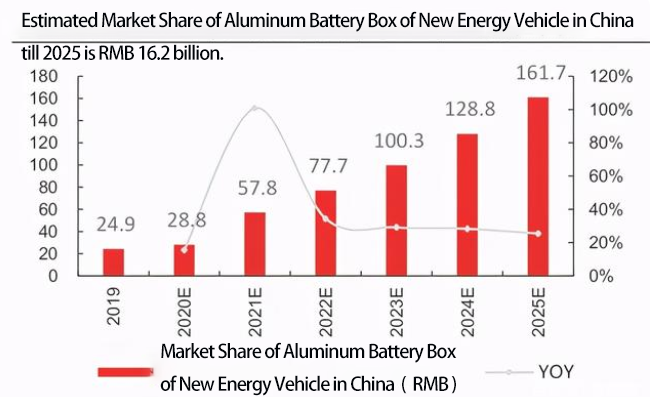

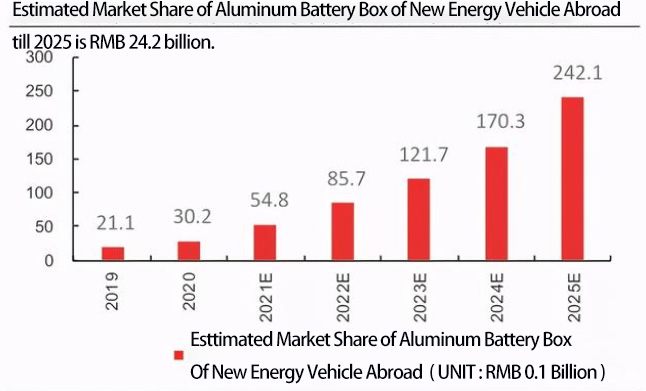

Motokari dzemagetsi dzakachena dzinoramba dzichiwedzera huwandu, uye nzvimbo yemusika yemabhokisi ebhatiri emotokari dzemagetsi matsva iri kukurumidza kuwedzera. Zvichienderana nefungidziro dzekutengesa dzepamusha uye dzepasirese dzemotokari dzesimba idzva, tinoverenga nzvimbo yemusika wemba yemabhokisi emagetsi ebhatiri remagetsi nekutora avhareji pamutengo weyuniti yemabhokisi matsva ebhatiri remagetsi:

Core fungidziro:

1) Huwandu hwekutengesa kwemotokari nyowani dzesimba muChina muna 2020 i1.25 miriyoni. Zvinoenderana neiyo Medium uye Yenguva refu Yekuvandudza Chirongwa cheMotokari Indasitiri yakapihwa nemaMinistries matatu nemakomisheni, zvine musoro kufunga kuti huwandu hwekutengesa kwemotokari nyowani dzevatyairi muChina muna 2025 huchasvika 6.34 miriyoni, uye kugadzirwa kwemhiri kwemakungwa kwemotokari nyowani dzemagetsi kuchasvika 8.07 miriyoni.

2) Huwandu hwekutengesa mudzimba hwemotokari dzemagetsi dzakachena hunoita makumi manomwe nenomwe muzana muna 2020, tichifunga kuti huwandu hwekutengesa huchaita 85% muna 2025.

3) The permeability yealuminium alloy bhatiri bhokisi uye bracket inochengetwa pa100%, uye kukosha kwebhasikoro rimwe chete RMB3000.

Mhedzisiro yekuverengera: inofungidzirwa kuti panosvika 2025, nzvimbo yemusika yemabhokisi ebhatiri emotokari nyowani dzevatyairi muChina uye mhiri kwemakungwa ichave inosvika RMB 16.2 bhiriyoni uye RMB 24.2 bhiriyoni, uye kukura kwechikamu kubva 2020 kusvika 2025 kuchave 41.2% uye 51.7%

Nguva yekutumira: May-16-2022